Aims · Working principles · Mobile components · Logbook · Results

The main objective is to achieve an optimal cleaning of the blades affected by the accumulation of dirt. Besides BladeCleaning must fulfill the following operational criteria to be competitive against traditional cleaning methods:

- Must be simple

- Must not be expensive

- Must not interfere in the operation of the wind farm in any way

- Must not require stopping of the turbine (cleaning operation will not affect turbine production)

- Must not require physical contact with the blades nor personnel access to the rotor

- Must not require qualified personnel to operate

- Must require minimum or no maintenance at all (reliable and robust)

- Must be easily adaptable to any model of turbine (replicable in any wind farm)

How it works:

Two main facts drove the design process of BladeCleaning:

- The sole effect of projecting pressurized water does not remove dirt from the blade

- Natural rainfall cleans the blades and recovers the power curve

Under this scenario, BladeCleaning was designed with the aim of replicating a rainfall event or, in other words, creating artificial rain that mimics the physical effects that rain causes over the spinning rotor. Therefore the cleaning of the blade occurs by the combination of several effects:

- Blade moisturizing: continued contact between water and the blade during a significant period of time induces the softening of the dirt layer and the chemical separation from the blade's surface

- Detergent effect: degreaser additives contribute to the separation of attached dirt and mosquitoes/beetles.

- Drag effect: rotating speed increases with the length of the blade and so does the centrifugal force. Unattached material from the blade tends to be displaced towards the end of the blade dragging dirt as it moves towards the blade tip finally leaving the blade due to the rotational movement of the rotor. This means that the cleaning is more efficient at the end of the blade (the part of the blade that generates more lift force)

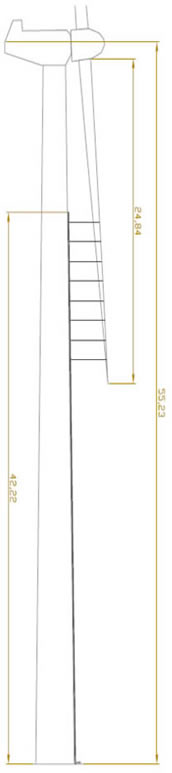

BladeCleaning system is comprised by a fixed installation of pipes on each turbine's tower and a mobile equipment that feeds them.

This mobile equipment is composed by a 17-20 cubic meter water tank (depending on the wind farm needs) that is pulled by a tractor to grant access to every turbine. A tank-truck can also be used if longer distances are to be made. The corporate image of the wind farm owner/contractor can be applied to the tank.

|

A water piston-pump is mounted on the chassis of the tank and is powered by the tractor gearbox reaching up to 50 bar with variable flow. This flexibility is the key to be able to operate the system on a wide range of wind conditions. This is achieved by regulating a knob in the pump and the tractor engine rpm.

Depending on the needs, a number of extra components can be fitted: water filter, emptying valve, variable length hoses, bottom chassis water load pump, etc. [Top]

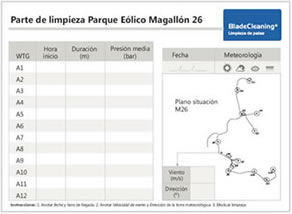

A logbook is designed for every installation to keep track of cleaning operations. It includes a map of the wind farm so the operator can plan the operation and maintain a record of meteorological data, duration of each cleaning and water pressure used. These data can be very useful for later detailed study of the cleaning implications.

This is the logbook for Magallón 26 wind farm:

|

|

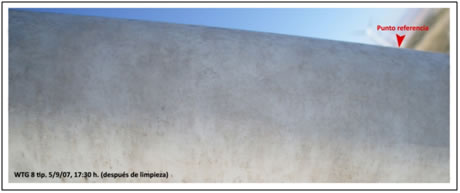

The folowing are pictures of the leading edge of a blade taken before and after a BladeCleaning operation in Magallon 26 wind farm:

|

|